TRIPLE THE CAPACITY

World’s most efficient snap-lock standing seam line

Growing popularity of snap-lock standing seam roofs has brought out that the machines currently in the market do not keep up with the production capacities needed. The production is slow, laborious and time-consuming, thereby jeopardizing delivery times and customer satisfaction. The machines are at constant risk to break down, as they are not designed for high-capacity production.

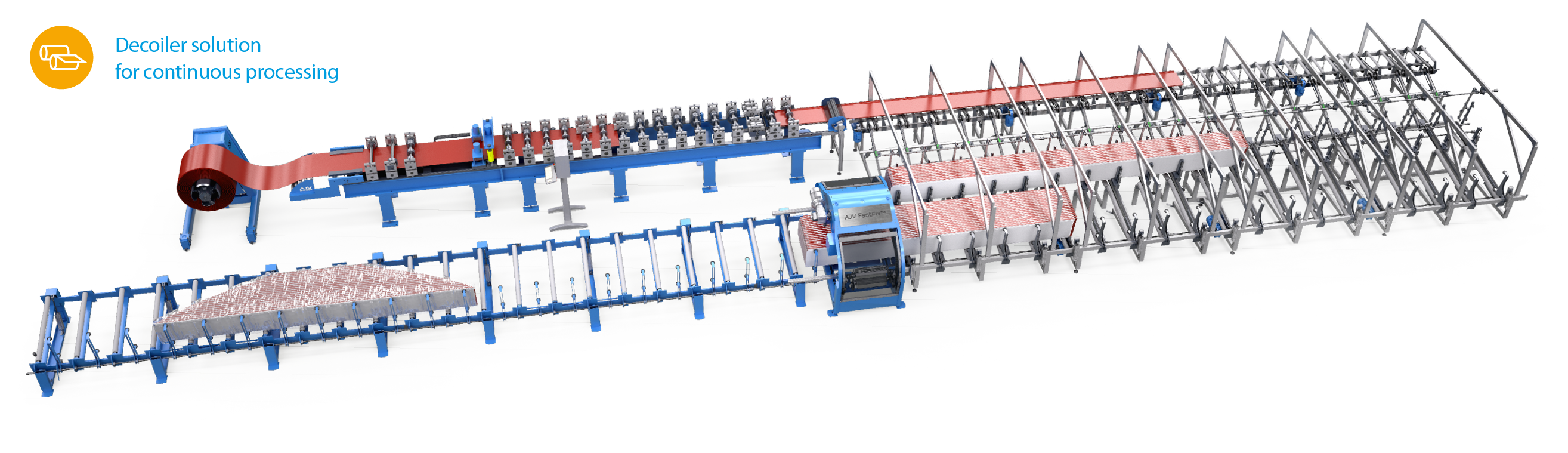

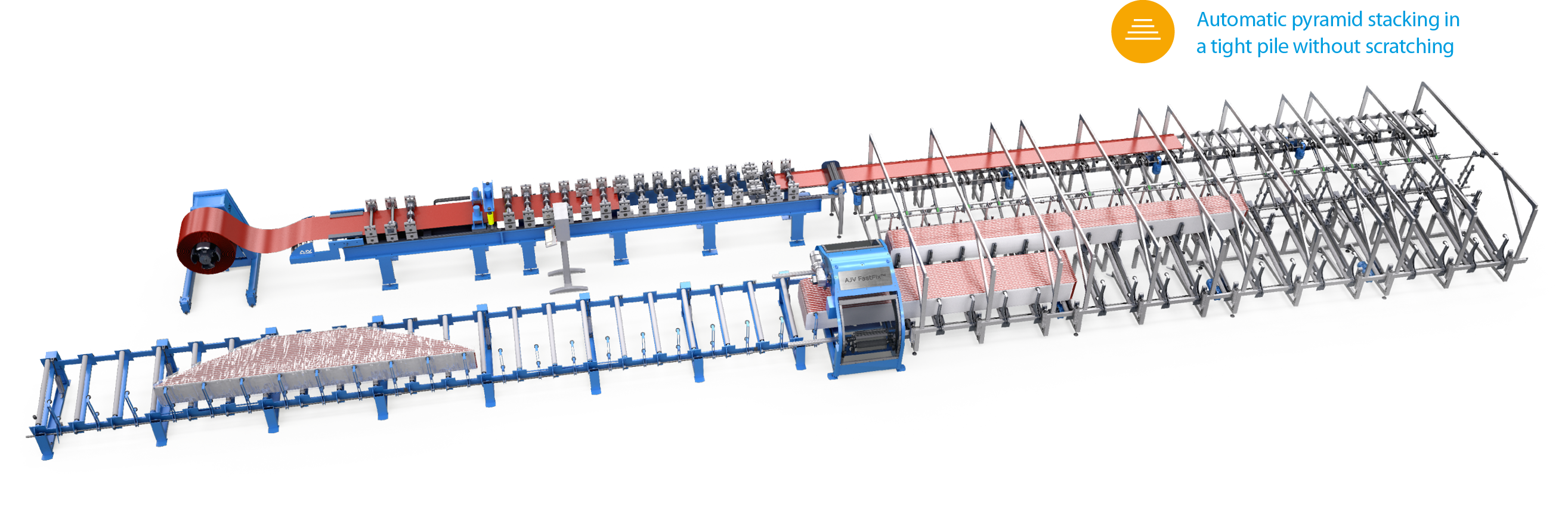

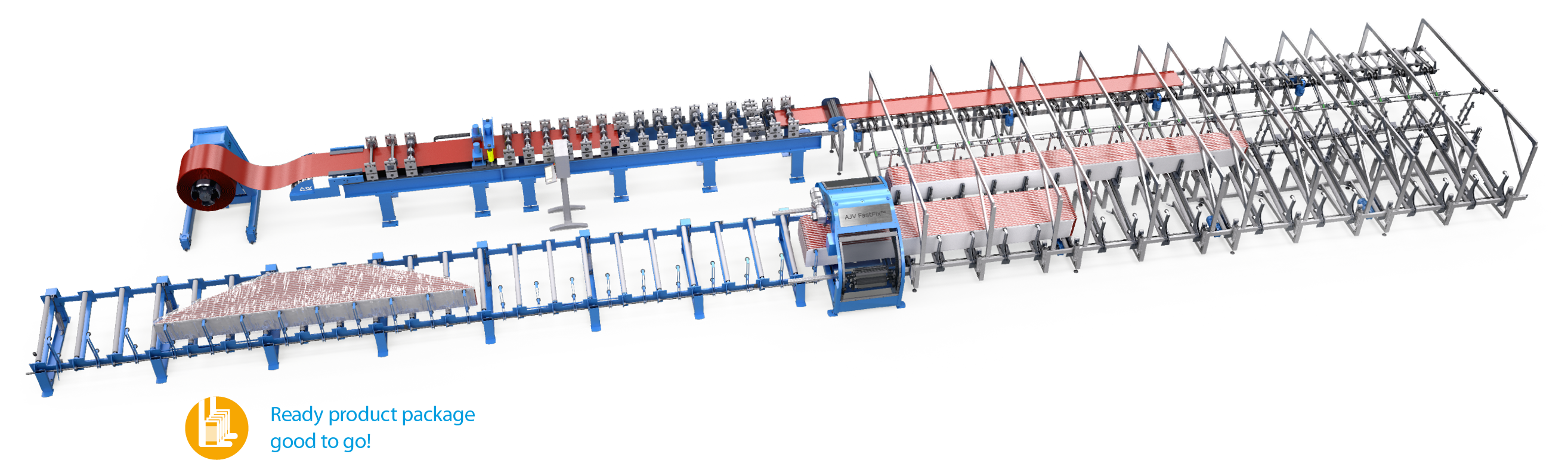

An awaited response to the market needs

with a totally new kind of technology

We at AJV have worked hard to develop a complete solution to this situation. Introducing AJV FastFix™, a totally new kind of roll-forming technology to turn the awkward production and market challenges to revolutionary business opportunities. With its fully automatic features and capacity increase never seen before, FastFix™ is designed to response to the pressing market needs at once.